Maximum precision down to the smallest detail

Your decision for future-proof technologies

Dreistern has delivered over 2,000 roll forming machines globally for a wide range of industries, and we have also fulfilled special customer requirements based on our engineering expertise. Dreisterns machines have an industry reputation of longevity, durability, verstility, precision, and ease of operation.

Roll forming machines

Innovative techniques for complex profiles

Flexible system concepts with optimized quality standards

The latest roll forming machines and innovative roll forming technologies have been our trademark for decades. With our roll forming techniques we are among the world’s market leaders. Clients benefit from our comprehensive expertise and our flexible roll forming concepts, which we engineer, develop, and implement to match your requirements.

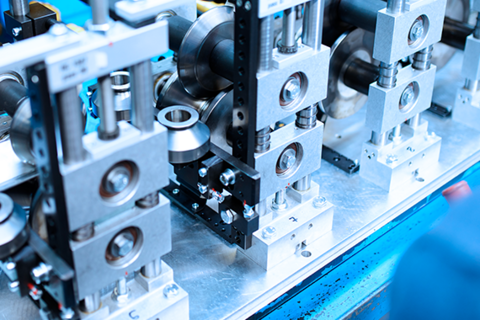

Roll forming dies

Total quality documented over 10,000 times

Tried and tested and immediately production-ready roll forming dies

Our outstanding position in the roll forming tool sector is evidenced simply by the number of over 10,000 complete tooling sets that we have supplied for open and welded profiles since the founding of the company.

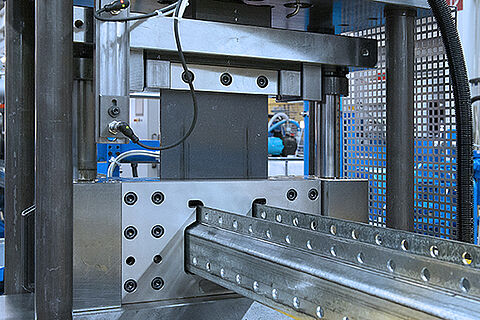

Pre- and post-punching systems

Maximum performance for extreme requirements

Low changeover times and minimum scrap generation during production

Your pre-punch equipment will be composed as a precision roller feeder working in conjunction with a punch press utilizing intelligent feed and tool technology for automatic setting up of pre-programmed hole patterns. In specific cases we implement rotary punching machines also. For post-punching, we implement concepts to achieve maximum production rates, which fulfil extreme requirements in respect of flexibility.

Cut-off machines

Ideal solutions for complex processes

Ideal cut-off machines combined with optimum cut-off processes

Cut-off machines must fulfill a wide range of technical requirements: our experts prepare individual solutions for you. This applies also for the selection of the cut-off process (sawing, shearing, punching or special cut-off process) as well as for important implementation details of the cut-off machine such as adjustment options or the profile or tube clamping equipment.

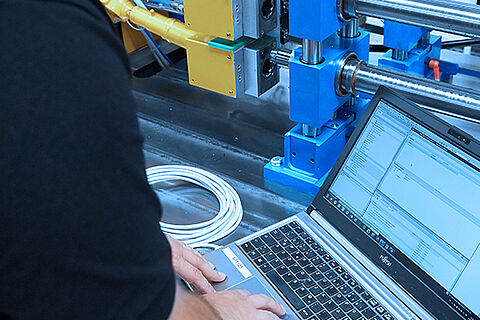

Control and Software

Comprehensive know-how for systematic processes

Maximum safety and optimum economy skillfully combined

Dreistern machine controls are the outcome of a methodical process. It starts with the design of the controller, followed by selection of suitable hardware and systems software programming and ends with professional commissioning that activates the full potential of a machine.

References

Special roll forming expertise for companies from a wide range of industries

International companies from a broad range of industries benefit from the comprehensive knowledge of our roll forming experts. Dreistern roll forming systems incorporating over 70 years of roll forming know-how are used by large, medium and small companies, of which a significant number are leaders in their market segment.

Here you can find out more about our different product worlds:

Contact our roll forming experts

Each process has its own special technological requirements, which is why your company too will have its own special questions about roll forming machines and processes: Our roll forming experts have the answers you need!

Franz Liebler

Engineering Manager

Phone +1 215 799-0220

Mail franz.liebler@dreistern.com

Dreistern Inc.

801 Tech Drive

Telford

PA 18969

USA